Wheels

At Comtires, we stock a wide selection of custom

wheels for customers in Ontario, CA, Chino, CA, Rancho Cucamonga, CA, and surrounding areas.

Whether you are looking for chrome, silver, machined or black custom wheels, we can help you pimp your ride the way you want to.

Before you start shopping for a new set of wheels, use our wheel buying guide below, and consider the advantages and disadvantages of different wheel materials in order to find the best wheel to suit your needs. If you have any questions during your research, simply contact us, call, or visit us.

Comtires’s Custom Wheel Buying Guide

Aluminum alloy wheels

Aluminum wheels (also known as alloy wheels) are built with a blend of two or more metallic elements, with Aluminum being the predominant metal.. The majority of wheels today are cast aluminum alloy, including the ones we sell.

Alloy wheels are light wheels with improved performance characteristics. These light wheels increase cornering and steering precision, and decrease road feedback for better braking response.

There are different manufacturing processes for custom wheels that make a difference in the wheels weight, performance and durability, keep reading for more on that below.

Steel wheels

are heavier wheels that provide vehicles with a lower center of gravity. Steel wheels are perfect for harsh road conditions in the snow or off-road over rugged terrain, but lack other performance capabilities because of the added weight.

Steel wheels are made with an alloy of iron and carbon. They are heavier but they’re more durable and can be easier to repair and refinish. Because of the way they’re made — cut out on a press and welded together — they don’t offer all the aesthetic spoke choices of other wheel types.

Chrome Wheels,

“Chrome” refers to the coating or finish of the wheels, not to the wheel materials themselves. Chrome wheels are alloy wheels that have been coated in a multi-layer chrome finish. They are perfect for drivers who are looking for something a tad snazzier and will make your vehicle stand out from the crowd.

While chrome wheels are known for their metallic mirrored shine, durability, and strength, they require regular attention and cleaning to maintain their visual appeal.

Carbon fiber composite wheels

are one of the best options for performance wheels. Most of today’s high-performance vehicles, like the Chevrolet Z06 Corvette, Ford Shelby Mustang GT350 and GT500, Koenigseggs, and Porsche 911 Turbo S either come standard with carbon-fiber wheels or offer them as an option.

They are still considered an exotic option for most people and their price just doesn’t make sense. As great as carbon fiber is, it’s brittle. It doesn’t flex like steel or aluminum and will shatter under excessive forces.

Custom Wheels & Rims: The Manufacturing Process

Cast Wheels:

Custom aluminum wheels are manufactured through a process of pouring molten aluminum into a mold. The shape of the wheel is formed through a process of gravity or low-pressure casting.

Cast wheels are the most common type of wheels that account for 90% of OE (Originally Equipped) and custom wheels that are found on most cars.

Flow Forged Wheels:

Different manufacturers call this process in a different way, it is also known as rotary forged, spung forged, flow forded, hybrid forged, etc.

The flow forged process combines low pressure-casting, heating, spinning, and precise pressurization to fill a mold with molten aluminum and shape the wheel. The process aligns the structure and molecules properties of the aluminum alloy, resulting in greater strength on the barrel of the wheel.

This hybrid manufacturing technique creates the wheel with a cast spoke face and a forged-like barrel.

Many manufacturers now have flow formed wheels lineup available as an intermediate option bridging the gap between cast and fully forged wheels. In fact this process is getting more cost effective that many manufacturers are moving to custom flow forged wheels rather than cast only wheels.

Flow forged wheels are suitable for most drivers who are looking to enhance the look and performance of their car at a lower price point.

Forged Wheels:

The forging process takes a solid piece of aluminum and molds the wheel through high heat and extreme pressure. The result is a light, dense, and strong wheel.

Custom forged wheels typically use aerospace-grade 6061 – T6 forged aluminum alloys as raw material which has the best mechanical property for engineers to work with.

This process involves a large piece of forged aluminum cylinder where the wheel design is realized by CNC machines. The forgings will go through a series of CNC operations to create the profile, width, offset, and spokes. Then skilled workers carefully hand apply all finishes to create the finished piece.

Since most forged wheels are individually made, there’s a wide variety of customization options, you can virtually customize every aspect of the wheels to make them fit your car the way you like it.

The costs of material, labor, engineering, and manufacturing processes make forged wheels very exclusive and come at a very high price point.

The right set of custom wheels depends on vehicle characteristics and desired ride quality. When choosing wheels for your car, truck, or SUV, consider the following:

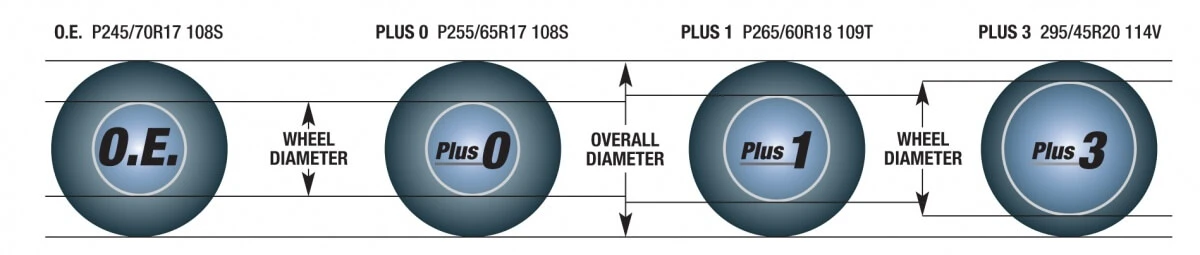

Overall Diameter:

Whether you are upsizing or downsizing the wheel diameter, it is recommended that the wheel and tire package keep the stock overall diameter.

Notice on the picture how the overall diameter remains the same, but the tire sidewall changes to accommodate the wheel diameter.

If you modify your suspension you can increase or decrease the overall diameter to accommodate for the overall diameter.

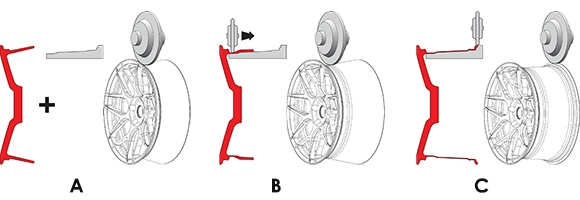

Wheel Width:

Wheel width is measured in inches and typically in ½” increments, and should be primarily determined by two considerations, purpose and clearance.

The width of the wheel goes hand by hand with the offset, which will be explained on the next point.

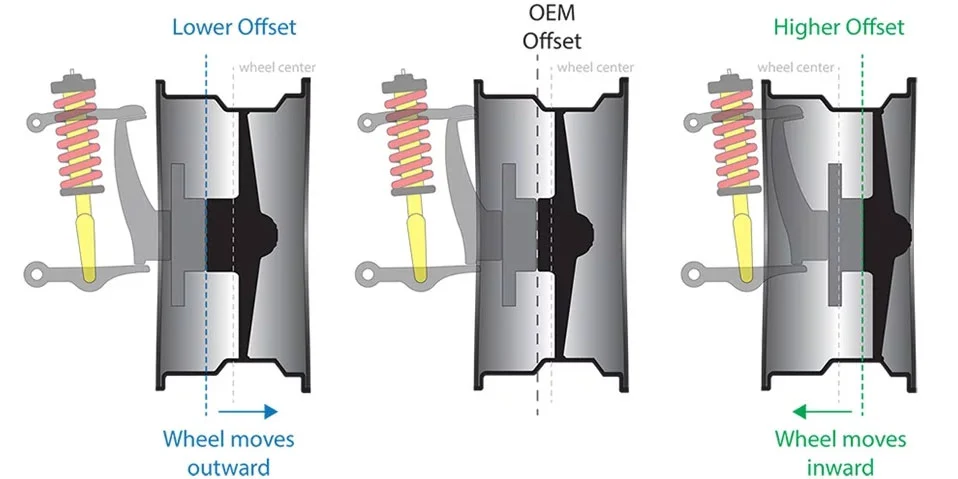

Wheel Offset:

Is the measurement from the center of the wheel to the wheel inside hub mounting surface. It is measured in mm.

Zero offset means that the hub mounting surface is even with the centerline of the wheel.

Positive offset means the hub mounting surface is located on the front half of the wheel face. The more positive the offset the more the wheel is going to be moved to the inside of the car, closer to the brakes and suspension.

Negative offset means the hub mounting surface is located on the back half of the wheel, the more negative it is the more the wheel will be pushed away from the brakes and suspension.

The offset required is determined by the vehicle stock wheel specifications, suspension or body modifications, and what wants to be achieved.

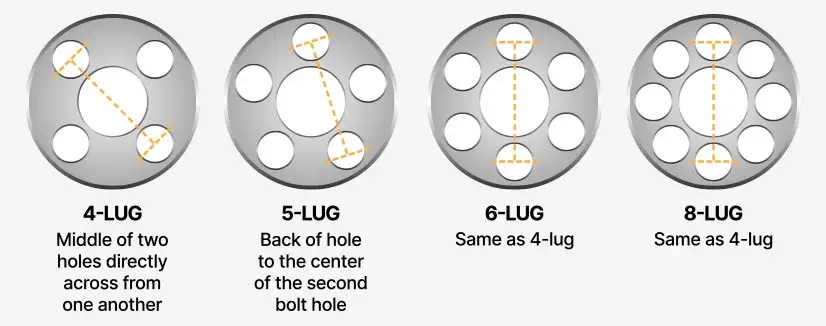

Bolt Pattern:

Bolt pattern is the number of lug holes in the wheel and the distance between them. It is usually composed of two numbers, the first one, representing the number of lugs, and the second representing the distance between them.

Some manufacturers make wheels with dual patterns so they can fit more vehicles. Even though they are called “universal” they only fit vehicles with the bolt patterns they have.

Center Bore:

Is the size of the center of the mounting hub of the wheel, this is an important number to consider, and it should match the size of your vehicle’s hub.

So, the vehicle’s weight rests on the hub of the wheel and not on the studs, bolts of the vehicle, this prevents vibrations, and most importantly, broken studs or bolts while driving.

If the wheel center bore does not match with the vehicle’s hub size, it’s possible to use a “hub ring” which fills the gap between the wheel center bore and the vehicle’s hub. Preventing vibration and catastrophic failure.

Our wheel configurator will show you what fits your car, truck or SUVs, whether it is stock or has some modifications.

Every customer’s criteria for buying custom wheels is different, so we urge you to contact us with your questions or concerns. Our service staff is comprised of wheel and rim experts who remain on the cutting edge of wheel style, configuration, and performance.

For the best wheel buying experience around, contact or visit us today.